What are short dental implants?

Short dental implants are designed to prevent the implant from penetrating anatomical structures, such as the maxillary sinus of the mandibular nerve, and provide long-term, stable treatment results in cases of bone volume loss (height and/or width deficiencies).

Short implants can be used in cases of upper and lower alveolar ridge bone deficiencies.

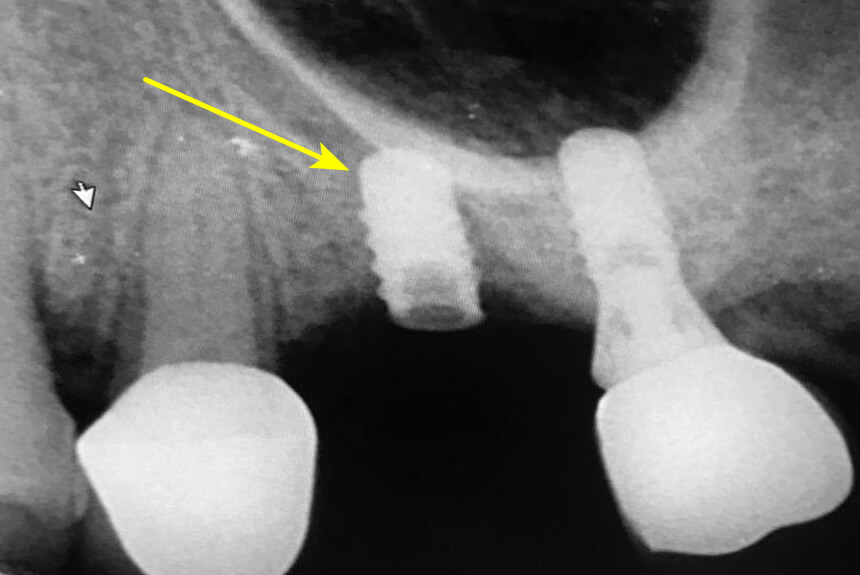

Image: short implants installed without affecting the alveolar nerve ↓

Short implants are used in many implant systems, including both plateau and screw root form designs (Ultrashort Plateau Root Form Implants).

Let’s look at some theory and practice. To hold a standard-sized implant (8 to 12 mm), the height of the alveolar ridge (bone) must be at least 12 mm, and the width must be at least 6 mm. If the bone height and/or width is not sufficient, it is recommended to perform an additional surgical procedure (sinus lift, bone grafting), which patients often call “bone augmentation”.

Such surgeries are common, and various osteoplastic materials are used in them. These surgeries are not so much technically complicated but rather difficult to predict, as successful bone augmentation is not just a matter of the surgeon’s skills but a combination of multiple factors. Such surgeries (bone grafting, sinus lift, alveolar ridge splitting) are not always successful. There is a high risk of complications (inflammation of the bone, osteomyelitis, maxillary sinusitis, facial numbness, autoimmune diseases, bone graft rejection, etc.), and the patient’s aftercare period can take years in some cases.

Short dental implants were developed to minimize the above risks and reduce the patient’s recovery time.

In the photo: a short implant of the “plateau” system is placed in the circumference of the maxillary sinus ↓

Advantages of short implants

Surgery without bone augmentation

There are certain protocols for placing dental implants. The classic screw-type implant protocol states that the implant length should be equal to the length of the dental crown designed to be placed on that implant. For example, if the tooth height is 1 cm, the implant must be at least 10 mm long. But on patients’ X-rays, we often see a bone height of 6 mm, which is certainly not enough. Hence, the originally intended implant protocol would be violated, and bone augmentation would be required to place a long implant. Such patients are usually offered a bone grafting procedure called a sinus lift.

A short implant makes it possible to avoid sinus lift surgery and damage to the maxillary sinus cavity.↓

Here, it is necessary to make a choice: either perform surgery to increase the bone volume or look for dental implants compatible with the bone height of 6 mm. The configuration of short dental implants of the “plateau” system, their protocols and long-term results (some of them serve for as long as 35 years) allow placing a crown that is three times longer than the implant itself. This is possible thanks to the greater surface area of the implant (due to the use of transversal “ribs” in the implant design).

The greater surface area ensures better stability of the implant in the bone and a long-term prosthetic result.

Owing to the design, the contact area of short plateau implants is also approximately four times greater than that of any standard screw-type implant.

In most cases, the use of short implants does not imply bone grafting surgery.

Implant shape

Another design feature of an implant of this system is a beveled neck and horizontal ribs, which allow for osseointegration at the neck of the placed implant. At all the congresses I have attended, the same question is asked when discussing complications after implantation of screw-type implants: “Why is the cortical bone destroyed at the top of the implant (where the abutment and crown are located)?”

Oral surgeons debate, argue, and hypothesize about this issue. But this problem is not observed in plateau-type implants. Besides the fact that there is no bone destruction at the implant neck, there is also an increase in bone growth. This effect was discovered many years ago by my colleagues from the United States.

Why does this happen? The reason is the design of the implant: a beveled neck, a larger implant surface area, and a tapered (not screwed) connection, which has no micromotion in the implant-abutment connection area.

Furthermore, plateau-type implants have a larger sulcus area, which creates conditions for the formation of the Haversian system (osteons). When this implant is placed in a bone cavity, blood penetrates between these large ribs and carries osteons with fibrin, which then build the bone. The usual screw implant, on the other hand, penetrates the bone with its threaded part and injures it, while it is possible to avoid this damage with the plateau-type implant, creating conditions for the formation of bone osteons and good implant stability in the future.

Conical implant-abutment connection

The non-screw conical connection has some advantages over the screw-abutment connection, where the attachment is ensured via a screw inside the implant.

Technically, the screw connection is not considered optimal, and the conical connection with well-fitted flats is seen as one of the best.

Pay attention to the video below. It shows a conical implant (above) and a screw-joint implant (below). You can clearly see when the screw-type implant demonstrates a noticeably greater micromotion of the abutment with the crown under load.

Also, there might be problems with the accuracy of crown placement against the dentition when applying a screw-type implant-abutment connection with a hex. Laboratory errors of 1 to 3 degrees are very common, which becomes a huge issue later when placing the crown in a clinical setting. If the connection is conical, this issue is eliminated.

Crown cementing in a laboratory setting

Another advantage of conical implants is the extra-oral (lab) cementation of the tooth crown. In plateau-type implants with the conical non-screwed abutment fixation, the dentist gets the crown already firmly cemented to the abutment while in a dental laboratory.

The dentist does not need to cement it — just insert it into the implant by applying light pressure, thereby avoiding cementation, which can lead to many complications described above.

In contrast, according to the classic scheme, cementing compound is applied to a crown, and the crown is then put on the dental stump or abutment and pressed down. The excess cement is squeezed out from under the crown while often getting under the gum. And this cement cannot always be removed correctly after the crown is fixed. The cement left in the mouth after placing the crown is a serious prerequisite for mucosal inflammation and bone destruction around the implant (peri-implantitis).

This is the most common problem with conventional screw-type implants.

Disadvantages of plateau-type implants

The main disadvantage of plateau-type implants is that special training is required for both surgeons and prosthodontists. Beginner dentists cannot work with such implants, as the accuracy of placement and proper preparation of the bone cavity are extremely important. Medical errors are not acceptable with these implants.

The cost of plateau-type implants is relatively above average.

There are not many dental clinics that work with plateau-type implants; so, you should consider that if you place such implants in one city, you are less likely to get help in another.

Patients do not need a follow-up after the placement of such implants, but if the patient wants to change something in the prosthesis after some time (crown color or shape), it is better to contact the same doctor who placed it.

Important fact about short implants

You should also know that short plateau-type implants are approved by the FDA (Food and Drug Administration) in the United States.

Plateau implants are produced by the following companies:

- BICON (USA)

- I-System (Switzerland)